BASF has chosen Finland's Harjavalta City as the first location for the production of battery materials to serve the European automotive market.

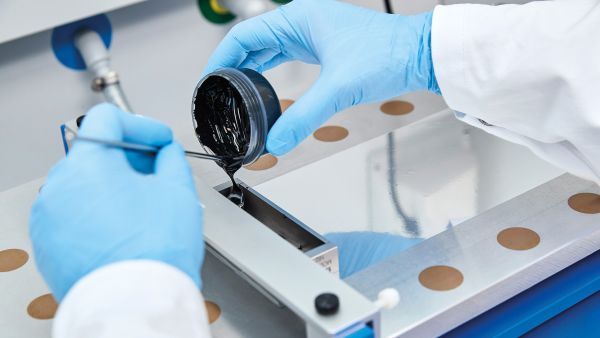

The plant will be built in the neighborhood of Norilsk Nickel (Nornickel) nickel and cobalt producer. This investment is part of BASF's step-by-step investment plan worth 400 million euros - announced last year - and is based on the initial production of battery materials, which began in Harjavalta in 2018. The start of the project is scheduled for the end of 2020, with BASF battery materials allowing about 300,000 electric vehicles a year.

The new Harjavalta plant will use local renewable energy sources such as water, wind and biomass. In addition, BASF and Nornickel have signed a long-term agreement for the supply of nickel and cobalt as raw materials from the Nornickel Metal Combustion Plant.

This partnership will establish a local and safe source of raw materials for battery production in Europe. The investment in the new plant in Finland strengthens BASF's support for the European Commission's agenda for a European supply chain for battery production.

BASF also evaluates other locations in Europe to build new battery materials production facilities.

"With Harjavalta's investment, BASF will be present in all major regions with local production and increased customer proximity, further sustaining the ever-growing electric vehicle market," said Kenneth Lane, President of the Division Catalysts from BASF. "Together with Nornickel, we create a strong platform that is able to align the efforts of leaders in the raw materials supply industry as well as battery technology and production."

"The location of the new BASF plant near the Nornickel metallurgical plant in Harjavalta will allow easy access to a local source of nickel and cobalt," said Jeffrey Lou, senior vice president of Battery Materials at BASF. "Our cathode materials with high nickel content are essential to deliver our customers energy density and vehicle autonomy.

With the help of this world-class production facility, BASF will be able to respond to the original European OEMs and battery cell suppliers with a secure supply and close collaboration."

Serghei Batekhin, Senior Vice President, Sales, Acquisitions and Innovation at Nornickel, said: "We are excited to expand our collaboration with BASF, one of our long-term strategic partners.The agreement is an important element of Nornickel's broader strategy to expand its presence on the global battery market and to establish a long-term collaboration with leading manufacturers of cathodic active materials. "

To learn more about BASF batteries and BASF's commitment to electrical mobility, please visit the website: https://catalysts.basf.com/products-and-industries/battery-materials.

You can find additional videos and photos on BASF research on battery materials and production facilities within TV and photo albums (please choose "battery" as search term).