The iron and steel production in Romania recorded a dramatic decline of 50% in the last 5 years, decreasing from 10.2 million tonnes in 2007 to 5.1 million in 2012, while the number of employees declined, but only by a fifth over the same period.

Romania, which in 1989 was the sixth largest steel producer in Europe, has recently lost three places in the ranking of iron and steel producing countries in Europe. After 1990, the domestic consumption of steel dropped dramatically to about 2.6 million tonnes in 2012, from 8 million tonnes in 1989. As a consequence, for the first time in 2012, Romania was no longer included in the World Steel Association ranking of iron and steel producing countries.

The effects of the global economic and financial crisis were strongly felt in 2009, when country’s GDP contracted by 7.1 %. Even though the world production of iron and steel decreased by 5.3% in 2009, Romania registered a steep 45.8% decrease injust one year.

In 2010, Romania’s iron and steel production recovered its losses from 2009, producing 5.4 million tonnes of iron and steel, with 1.1 million tonnes (26%) more than in 2009. The production growth was due, to some extent, to the implementation of the Romanian metallurgy restructuring programs according to the European Union’s requirements, which led to modernization of several steel companies. Despite the 2010 growth, the production of iron and steel registered a small decline in 2011 and 2012, of 1.1% and 6.2% respectively.

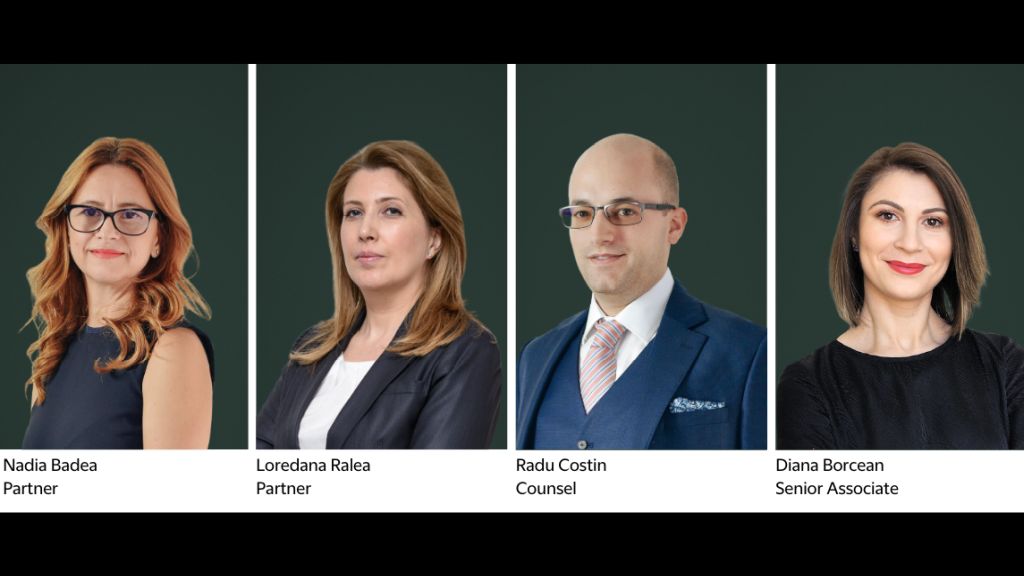

Because of the iron and steel industry privatization that took place over the past 20 years, a number of metallurgy groups decided to invest in Romania, and now they dominate the local industry. The most important ones are ArcelorMittal, Mechel, TMK and Tenaris, which add to almost 87% of the sector’s turnover, employing 82% of the industry’s workforce.

An analysis made by Ziarul Financiar business daily on the major steel production plants in recent years shows that the main cause for steel production decrease was the low production at the plant in Galati owned by ArcelorMittal (formerly named Sidex). By 2011, the production of steel at AcelorMittal Galati was reduced by 57% compared to 2007. According to the company’s representatives, the significant decrease in the plant’s production was due to a lower demand for metal products and the strong competition exerted by producers in countries that are not part of the European Union, where energy costs are less than half compared to those of ArcelorMittal Galati.

CHINA, THE FIERCE COMPETITOR

Worldwide, the production of iron and steel reached a record of 2,611 million tonnes in 2012, outperforming the 2011 level by 1.5%. China increased its production by 3.9% and retained its leadership position, yielding 52.2% of the global output, at 1,363 million tonnes of iron and steel. Production in Japan remained flat at 189 million tonnes, representing a 7.2% market share.

The United States held the third position, producing 122 million tonnes, up 3.6% and accounting for 4.6% of the total global output. Production in Europe, which accounts for 10% of total production, was gloomy, declining by 4%.

Global steel demand is expected to improve gradually in 2013 compared to 2012 levels, driven by emerging and developing economies. Adding to the pressure on steelmakers profitability is China’s growing capacity, which is denting steel prices around the world. After a decade of rapid expansion, Chinese firms are now responsible for more than half of global production. The incredible growth is primarily driven by government pro-growth policies and large investments in infrastructure. In the United States the increase in production is supported by the Federal Reserve attempts to sustain the US economy, a strong momentum in the automotive sector and recovery of the construction market. World steel industries are now undergoing a restructuring phase with all sorts of mergers and acquisitions taking place all around the world. The key market players are subjected to fierce competition from the new companies from developing economies.

GOING FORWARD

In Romania, the automotive and the construction industry continues to exert a strong influence on the metallurgy industry. The investments of Renault and Ford increased the country's car production by 36% in the first half of 2013, and for the first time in history, Romania managed to outdo Belgium automobile production. This sector is expected tocontinue to increase, following a recent increase in capacity at Ford's Craiova plant. BMI also forecasts positive figures for the Romanian automotive production between 2013 and 2017 that should have a positive influence in sustaining growth for the iron and steel industry.

In contrast, the construction sector, which is also of great importance to the steel industry, has registered one of the most significant falls during the crisis years. The poor performance registered since 2009 has had a damaging effect on the production of steel construction products. For 2013, BMI expects a real growth of 1.9% in the construction industry, which means a return to growth after a 0.9% contraction in 2012. Over the period 2014-2017, Romania's construction market is expected to further expand at an annual rate of 3.2%.

The employee productivity was also hit particularly hard by the decrease in orders. In 2009 it dropped to 96 tonnes of crude steel per employee, representing a 42% decrease compared to 2007, when the highest level was recorded. On top of this, the steel industry is now facing skills shortages, as qualified workers started to migrate to other parts of the EU in search of higher pay and better employment opportunities. This will bring companies face to face with a fundamental choice of investing in technologies and skills or to further cut down jobs.

As previously mentioned, the biggest impact on the local metallurgical industry comes from high energy prices, which represents two-fifths of steelmakers operating costs. Since the renewable energy tax and the cogeneration tax will continue to increase from year to year, it is estimated that by 2015 these will lead to an increase in energy prices of minimum 50%. Because of this, earlier this year, the metallurgy sector requested the Ministry of Economy to modify the legislation in order to enable them to conclude long-term contracts in the electricity and natural gas sector under more favorable conditions. All major countries that registered an increase in production of iron and steel had the government support, which is why legislative measures should be the first step for the metallurgy sector recovery in Romania as well.

The recovery can only be driven by innovation, improving energy efficiencies and increasing demand for key products. The industry requires a new political strategy that comprises lowering the tax on reinvested profit, applying a differentiated tax on profits made from export and creating fiscal facilities in order to enable companies to lower their costs to a European level.

Joint venture projects with regional neighbours, such as the bridge at Vidin-Calafat, linking Bulgaria and Romania, will improve trade relations and increase country’s export potential. Because steel is closely linked to many other downstream industrial sectors, positive growth in the autos and construction industry should also lift up the iron and steel industry.

The importance of iron and steel industry is in no doubt. Last year, the metallurgical companies have covered 11% of the country’s exports. Therefore, the Romanian economy benefits from having some of the world’s biggest steel producers, but, without government support, the increase in energy prices will continue to put further pressure on margins and may force further temporary closures of plants, or in the worst-case scenario force the steel companies to look to other countries with cheaper energy prices.