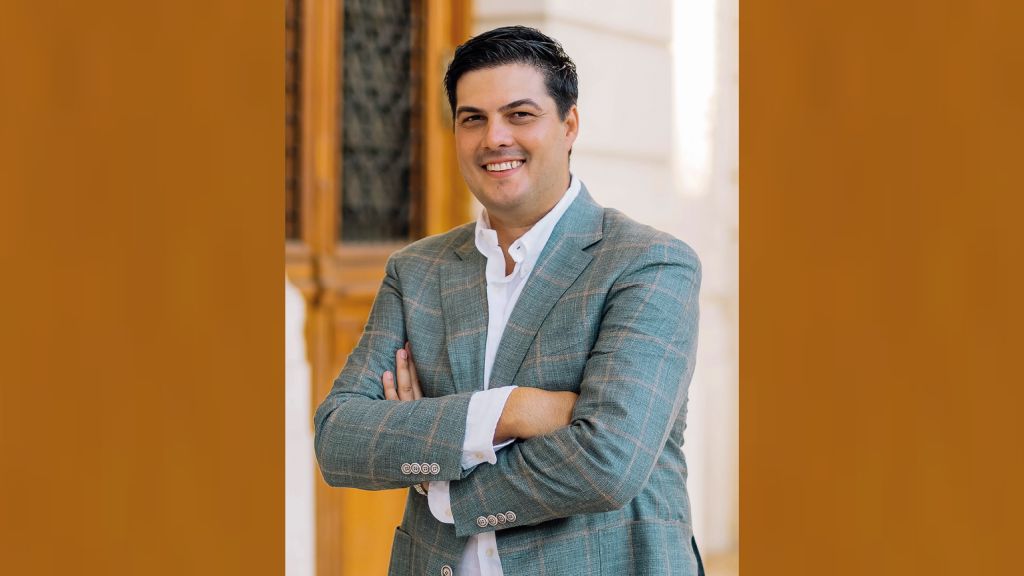

Q: You have around 25 years of experience in the construction-equipment sector in Romania. What initially drew you to this field and how did the transition from marketing & sales to a top leadership role shape your vision?

Mr. RAZVAN MARCU: I was pretty lucky to be part of a Romanian family business company (former Marcom RMC’94). Being always around my parents, in a technical environment, I have been attracted from the beginning by the construction machinery and similar products. My background is in economics but I always believed that you can follow whatever other passion you want. And mine was related to machinery!

Q: KUHN ROMANIA operates in a market that is highly cyclical and closely linked to infrastructure investment. How have you managed strategy and growth in the face of volatility in public funding and project pipelines?

Mr. RAZVAN MARCU: Romania is a particular market, with a great development ahead. Maybe not always at the correct speed or on a continuous positive path. We grew up in this environment that is sometimes marked by slow down and we became very resilient. It is also true that we were forced to rethink our business product range so that in difficult times in one sector (for example infrastructure) we move our focus towards other areas. Our business today is organized in 3 divisions : Construction and Mining, Crushing and Screening and Lifting Equipment.

Q: As one of the market leaders in large earth-moving equipment, what are the emerging trends in terms of machine technology (hybrid, electric, telematics) and how is KUHN ROMANIA preparing its product portfolio accordingly?

Mr. RAZVAN MARCU: The Romanian customer reacts in 2 ways when he is buying: when EU funds are available, he buys the most modern technology as big part of the investment is subsidized by EU and the Romanian Government. When challenging times arrive, like the actual ones, he is moving towards a more conservative direction and buys influenced more by the survival instinct. Nevertheless, I have to mention that we see a trend in the case of the big customers (Romanian of foreign) to invest in modern technology and here we can include machines with telematics (to increase the efficiency and productivity) and in the hybrid technology in order to increase the fuel efficiency. The electric technology in the earthmoving equipment is not very popular as the prices of the machines are couple of times higher versus conventional machines and still we have a big issue regarding the charging methods. Let’s not forget that most of the construction machinery works in remote areas, most of the times without electricity cover.

Q: The after-sales service network is critical in this industry. What are your priorities for service-infrastructure expansion, parts availability and customer support, especially in remote or rural construction zones?

Mr. RAZVAN MARCU: Our philosophy is clear, we have to be as close as possible to our customers jobsites. As underlined, the earthmoving machinery is working in remote areas so proximity of our support is very important. We are investing in 2025-2027 almost 20 million euros in 4 new very modern offices (Bucharest, Turda, Timisoara, Roman) that will support our activity, will make us respond faster, be closer to our customers.

Q: Labor force shortage and ageing workforce in the technical/servicing side have been highlighted as major issues. How are you addressing recruitment, training and retention of technical staff in KUHN ROMANIA?

Mr. RAZVAN MARCU: I have to admit that the entire market is facing a labor shortage but in the same time the machines are becoming very modern and the level of knowledge to inspect and diagnose is increasing. So, it is not enough that we do not find sufficient engineers, we also have to select the best prepared ones in order to keep the machines under control. We try to attract young engineers after graduating the academies, we extend the training period (office and field), we use the parenting training mode (assign a more experienced engineer to support on daily base), we do all sorts of trainings and meetings and not last, we also try to have fun in our team so people feel this is not only a simple job place.

Q: From an ESG perspective, how is KUHN ROMANIA aligning with sustainability goals in construction equipment—whether via lower emissions machines, circular-economy parts, or green financing packages for clients?

Mr. RAZVAN MARCU: We represent some of the best machinery producers in the world and their technologies are the most modern and environmental friendly. Komatsu, our core business partner, is very well know in the world for producing the most reliable hybrid and electric technology.

Q: How do you segment your customer base (infrastructure contractors, quarries/mining, rental companies) and what distinct strategies do you apply for each segment in terms of equipment selection, fleet management and financing?

Mr. RAZVAN MARCU: Our main business is related to infrastructure and here we can mention: construction companies, rock and gravel industry, concrete and asphalt suppliers and other industry related players. Each application requires similar but different machines in terms of configuration. Also, depending of the customer type and needs, we are offering different financing schemes based on their needs. Related to this, I am very happy to announce that starting with March 2026, KOMATSU FINANCE division will be available for the Romanian customers.

Q: The Romanian construction-equipment market is projected to potentially contract in certain cases due to weak fund absorption. How do you manage risk in such scenarios and keep your business agile?

Mr. RAZVAN MARCU: 2025 is one of those years that face a lack of EU funds for machinery acquisition so we also see a big contraction of the demand, reaching a level of 60% versus 2023 that was a great year from EU funds absorption point of view. As explained earlier, we target other areas too. With very good results in 2024 and 2025 were the sales of MANTSINEN big material handling machines in the Constanta port. This projects counterbalanced the decrease in the demand from earthmoving equipment.

Q: Looking ahead to the next 5-10 years, which disruptive trends do you expect and how is KUHN ROMANIA positioning itself for that future?

Mr. RAZVAN MARCU: In our industry we can already see a clear transition from conventional machines (full operator control) towards guidance or semi-automated machines (partial operator control) and in the end towards full automated machines (no operator control). I would say the first transition will be very popular in the next 5 to 10 years as the technology is taking over the lack of ultra trained people.

Q: Finally, what advice would you offer to young professionals or entrepreneurs who are considering a career in the construction-equipment industry in Romania—what do you believe the key personal and professional attributes are for success?

Mr. RAZVAN MARCU: The construction equipment industry is vibrating, challenging and full of opportunities. My advice is simple: be curious, be persistent, and stay true to your ideas. This field rewards people who think independently, who respect the teams they work with, and who are willing to grow every day. If you bring passion and integrity into your work, you can build an extraordinary career and contribute to the development of a country that still has so much potential ahead.

You can also find the full interview in the document below: