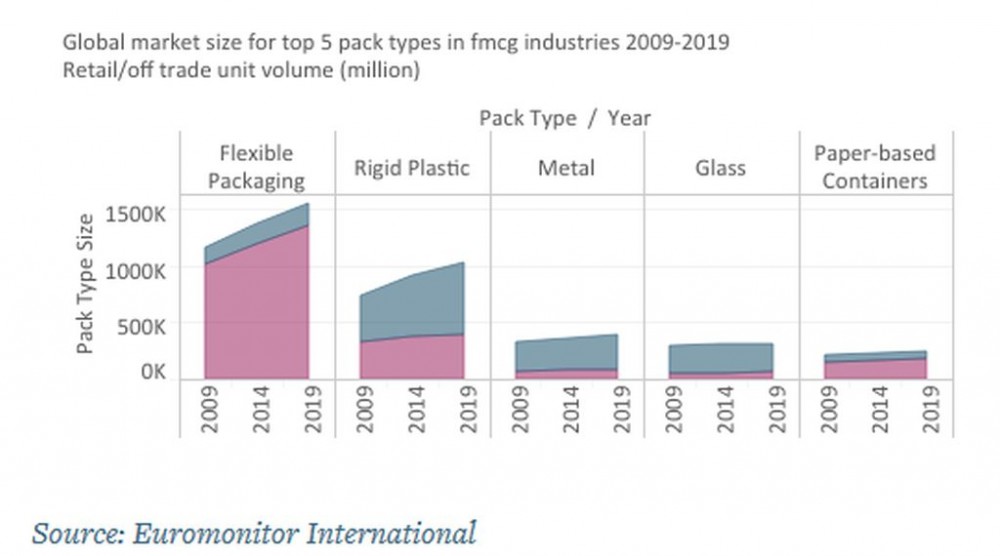

Since commercial inception, flexible packaging has quickly become the most important packaging format in household goods. The versatility, low cost and resource efficiency attracted many manufacturers to flexible packaging.

According to Euromonitor International, flexible packaging accounted for 41% of total packaging globally in 2019, and 75% of this was made up of flexible plastic. The next two largest formats are flexible paper (6%) used primarily for gum and confectionery and flexible aluminium/plastic (5%) for coffee packaging. Though the top-three formats will experience growth in the coming years, flexible packaging is expected to grow ahead of all other formats.

Food uses the most packaging of any industry, generating 2.2 trillion units in 2019, according to Euromonitor International. More than half of food products are packaged in flexible packaging globally. This type of packaging offers a valuable and sustainable role in guarding against food waste.

Given its versatility and role in protecting products, flexible packaging will remain important now and in the future. Whilst packaging sustainability may not be the top priority during the coronavirus pandemic, recovery in consumption is expected as demand grows for consumer container options that are recyclable, compostable, biodegradable and away from single-use plastics in the future. New solutions will target better recyclability and the reuse of existing waste materials to reduce fossil inputs. As such, a global shift from multi-material to mono-material films, such as flexible mono-plastic and flexible paper, is expected.

Mono-materials are one of the soundest routes to generating more sustainable flexible packaging. These materials eliminate the need for material separation and risks of tainting a recycling stream, making recyclability easier to achieve. However, use has been somewhat restricted due to their inability to achieve the same high-protection barriers as multilayer films. For this reason, their use is largely concentrated on low-moisture products, such as sugar confectionery, sweet biscuits and powder detergents.

Mono-plastics may lose to......................................................

By: Trishna Shah

The article is property of Euromonitor International, a market research provider, and can be read in full here.