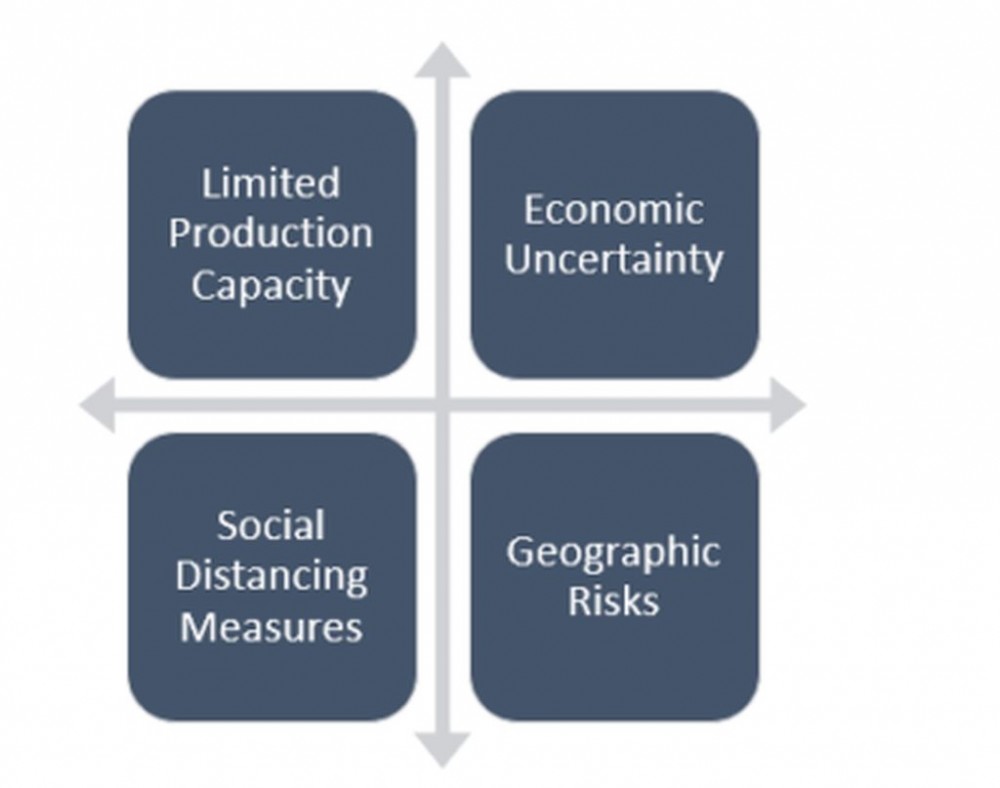

Manufacturing businesses around the globe face numerous challenges arising from the Coronavirus pandemic. Disrupted supply chains, social distancing measures, production capacity issues and economic uncertainty are the key challenges that can be tackled by increasing investments in production automation and sales channels.

Risks Affecting Global Manufacturing Industry

Production capacity issues to impact manufacturing operations

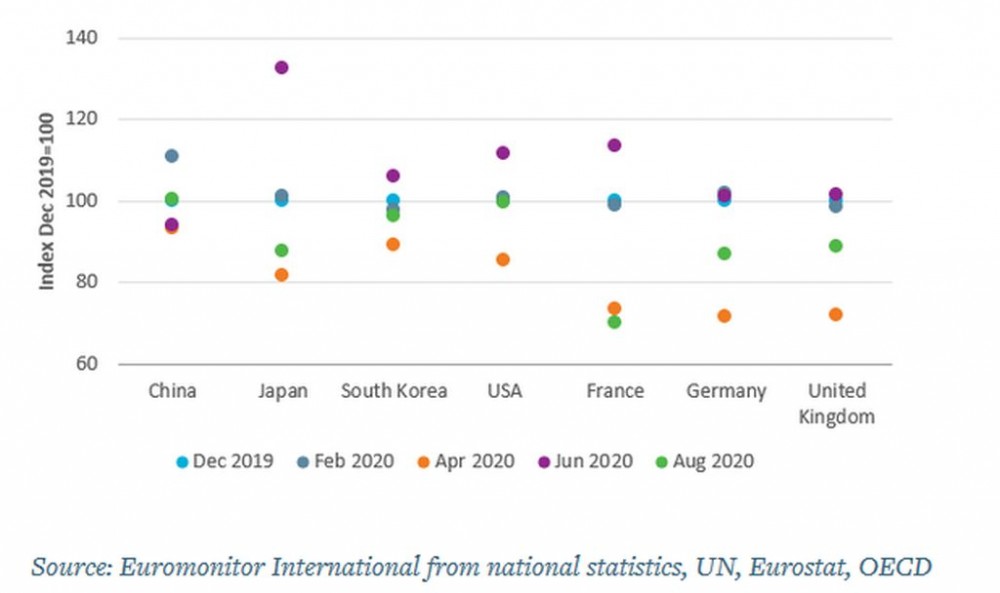

Production capacity and supply chain issues are forecast to continue, in turn hindering the performance of manufacturing companies. The global supply chain problems are likely to persist until Q4 2020 as it will require significant capital and time investments from the companies until supply and transportation networks are fully restored. Moreover, monthly industrial production index dynamics in the largest economies also indicate that the manufacturing industry continues to operate below optimal capacity levels, resulting in potential supply issues.

Monthly Industrial Production Index in Selected Countries, Dec 2019-Aug 2020 (Forecast)

Economic uncertainty erodes B2B and B2C demand

In addition to supply chain issues, the manufacturing industry is expected to face increased risk from rising global economic uncertainty. This is likely to erode some of the demand for B2B and B2C goods and create additional risks for manufacturing companies. It remains uncertain for how long the global manufacturing sector will feel the effects of COVID-19, although taking, for example, the Great Recession back in 2008-2009 indicates that it might take up to seven years for the manufacturing industry to fully recover. In that instance, US manufacturing output fell by 20% in 2008 and did not fully recover until 2015.

Social distancing measures to constrain faster production growth

Social distancing measures is another issue that continues to hinder the performance of the manufacturing industry. Prevalence of social distancing measures means that not all employees can return to work at once, thus manufacturing companies cannot operate at full capacity and this further delays supply chain recovery. Moreover, companies also face increased healthcare risks, and failure to contain the spread of COVID-19 among employees could result in extended production shutdowns.

High reliance on mega suppliers creates supply risks

The COVID-19 pandemic and associated factory lockdowns.......................................................................................................

The article is property of Euromonitor International, a market research provider, and can be read in full here.